SPONSOR INTERVIEW

Dr. Abolfazl Mohebbi, CTO at Moxietec

Can you tell us about your role and what your responsibilities entail?

As the Chief Technology Officer (CTO) at Moxietec, I oversee team management, technology development and day-to-day operations.

Can you explain what your company does and how it fits within the supply chain?

Moxietec is an American IP-enabled company with innovative and proprietary technology that facilitates the production of thick thermoplastic foamed parts, making them Lighter, Faster and Greener. We have been establishing connections with manufacturing companies, offering engineering solutions, and positioning ourselves as reliable turn-key providers for sustainable product development.

The Moxietec technology pushes the boundaries of part design in the plastics industry. With this technology, concerns about developing dimensionally stable products with large cross-sectional thickness are a thing of the past. The previous design limitation for part thickness was 0.5 inches, but with Moxietec technology, we have demonstrated consistent results of up to 9 inches. Thanks to the foam nature of the technology, products can now be created larger and lighter, with some products experiencing up to 80% weight reduction.

Sustainability takes precedence at Moxietec, aiming to make planet Earth a better and cleaner place for its inhabitants. Our innovative and world-class research team at Moxietec is actively working on various formulation developments, utilizing recycled polymers, and introducing proprietary additives to design value-added and sustainable products, thereby reducing the carbon footprint. Our ultimate goal is to develop plastic products with a high recycled content across different industry sectors, meeting their specific application needs.

What innovative new trend or technology is particularly interesting for you currently?

Considering recent developments within Moxietec and our focus on sustainable manufacturing, I am particularly fascinated by the current trend in advanced materials and technologies that contribute to environmental discussion. Our proprietary technology, which enables the production of thick thermoplastic foamed parts with significant weight reduction, perfectly aligns with this trend. The shift towards circular economy practices and sustainable solutions resonates with Moxietec's commitment to making a positive impact on the environment.

Exploring innovations related to recycling, formulation developments, and the use of recycled polymers in product design is especially exciting for me. Witnessing the transformative effects of these technologies on part design and manufacturing reinforces the importance of our work at Moxietec. As we actively contribute to reducing the carbon footprint through our research and sustainable product development, staying alongside these trends allows us to remain at the forefront of positive change in the industry.

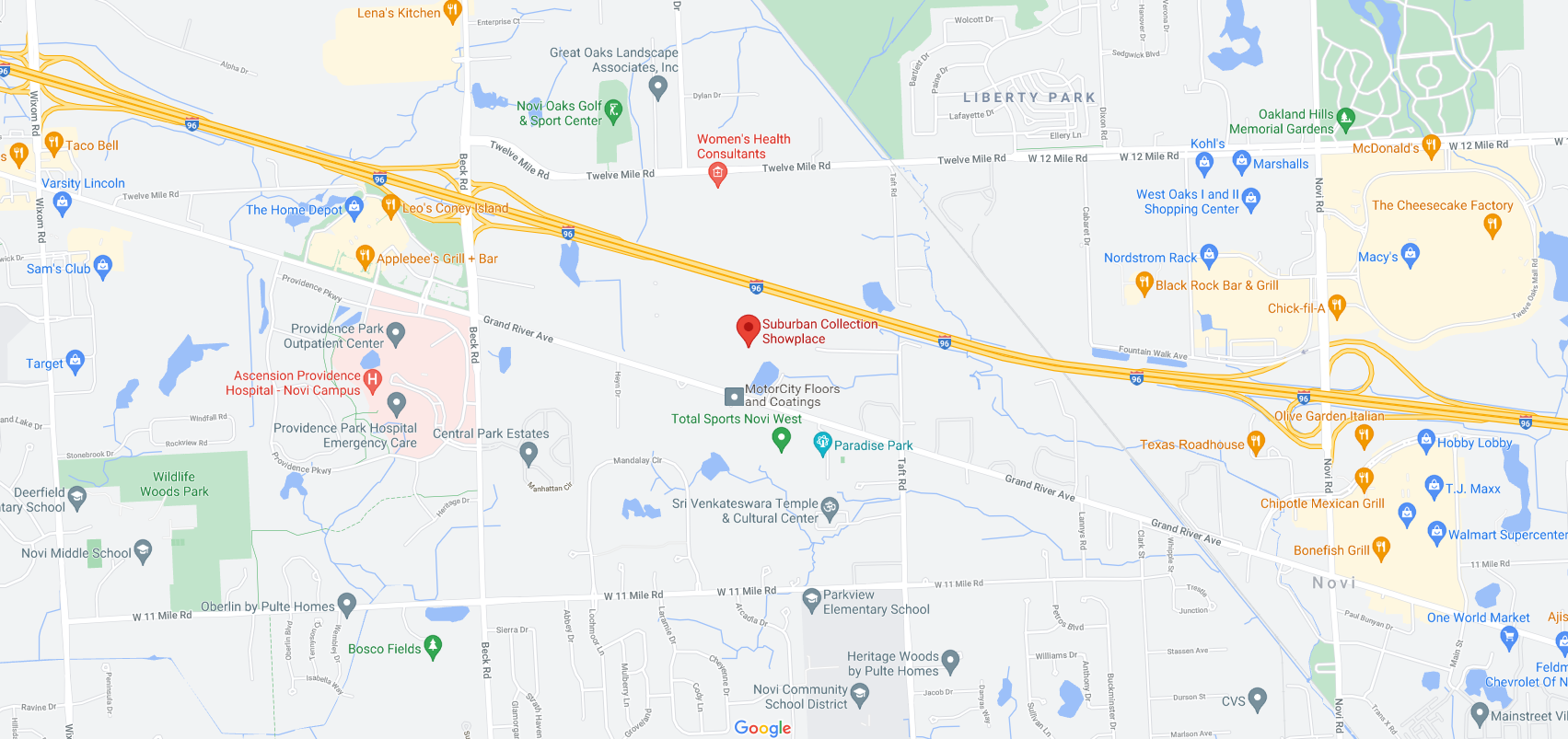

What are you most excited about for Foam Expo 2024?

I am particularly excited about Foam Expo 2024 for several reasons. Firstly, it provides an excellent platform for networking and fostering connections within the industry, allowing us to share insights and explore potential collaborations. Additionally, I am eager to stay updated on the latest advancements in foam-related technologies and innovations showcased at the expo. This event offers a valuable opportunity to engage with industry leaders, discover emerging trends, and contribute to the ongoing dialogue surrounding foam manufacturing. I look forward to gaining fresh perspectives, expanding our network, and staying at the forefront of developments in our field.

Why should attendees visit your booth?

There are compelling advantages to exploring Moxietec technology at our booth:

1. Sustainable Light-Weighting:

Our technology enables a significant reduction in raw material consumption compared to traditional plastic manufacturing methods. This not only contributes to environmental sustainability but also has a trickle-down effect, as lighter parts require less energy for transportation, ultimately reducing their carbon footprint on the Earth.

2. Cost-Efficient Manufacturing:

Moxietec technology streamlines the cycle time of plastic/composite manufacturing, leading to substantial cost saving in part production. This efficiency improvement directly translates into a more economical and competitive manufacturing process.

3. Versatility in Applications:

Moxietec has broadened the horizons of manufacturing, allowing plastics to be applied in novel spaces. The resulting robust parts can serve as viable alternatives to metals and concrete, showcasing the versatility and innovation inherent in our technology.

If you had to be stuck on a desert island with one famous person (past or present), who would this be?

Einstein